Angela’s Time at Purdue University Northwest’s CMEC

- Hace Mas

- Feb 27, 2025

- 4 min read

Updated: Mar 24, 2025

Where does a product designer go for training? For our founder, it was a part-time job designing products at Purdue University Northwest’s Commercialization Manufacturing and Excellence Center (CMEC). Over two and a half years, Angela worked with many small businesses, helping them turn napkin sketches into fully functional prototypes.

As a Design & Development Technician, she played a crucial role in CMEC’s six-step commercialization pipeline, which helps entrepreneurs validate their ideas, develop prototypes, and prepare for manufacturing. Each step of this pipeline ensures that businesses build strong foundations before investing in full-scale production. The process involves (Projects - Commercialization and Manufacturing Excellence Center - Purdue University Northwest, 2022):

Concept Viability – Entrepreneurs meet with CMEC’s Entrepreneur-in-Residence to assess their product ideas and understand how far along they are in development.

Entrepreneurial Viability – Ensuring the entrepreneur is prepared to communicate their vision clearly and open to learning and professional guidance.

Intellectual Property Viability – CMEC works with Hartman Global Intellectual Property Law to evaluate whether the entrepreneur’s idea can be protected under federal patent laws.

Customer Viability – Entrepreneurs are encouraged to survey at least 100 potential customers to determine market demand and refine their concepts accordingly.

Product Viability – This is where CAD models, prototypes, testing, refinements, and rebuilds take place. Angela was heavily involved in this step.

Commercial Manufacturing Viability – Once a working prototype is finalized and demand is validated, CMEC assists with finding suitable manufacturing methods.

Angela specialized in the Product Viability phase, where she used CAD software, 3D printers, CNC machines, and fabrication tools to help entrepreneurs refine their designs and build manufacturing ready prototypes. Through this work, she gained hands-on experience with various industries, each with its own unique challenges. Some of her most noteworthy projects included Dynamic Framer, a veterinary surgical tool, and a custom display stand.

Key Projects Angela Worked On

The Dynamic Framer

The Dynamic Framer was a tool designed to help carpenters, home improvement enthusiasts, and construction workers quickly and safely install wall studs while ensuring they meet safety regulations on the first try. This project began before Angela joined CMEC, but when she took over, she inherited:

Early rough prototypes made by the entrepreneurs

A partially developed CAD model

An incomplete prototype built at CMEC

Angela worked with the founders of Dynamic Framer to finalize the CAD model, improve the design, and create a fully functional prototype. After a few iterations, she helped them develop a manufacturing-ready version of the tool. Today, the Dynamic Framer team has obtained patent protection and working toward manufacturing, using the finalized designs Angela developed.

You can learn more about The Dynamic Framer from their website: Dynamic Framer Website

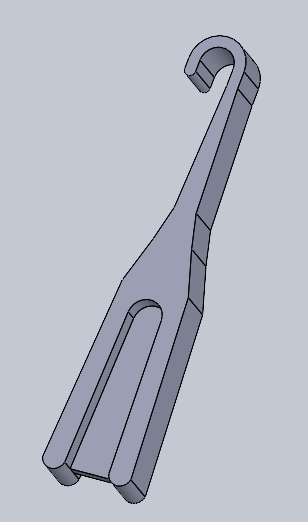

Veterinary Surgical Clamp

One of the projects Angela is most proud of is a veterinary surgical tool designed to help veterinarians perform life-saving procedures. The problem was clear: traditional surgical clamps were too large to be effective for small animals. A veterinarian came to CMEC looking for help in designing a tool that could hold open incisions during surgery without causing unnecessary strain or damage.

Angela worked directly with the veterinarian, starting with hand-drawn napkin sketches. She then:

Converted the rough sketches into precise CAD models

3D printed prototypes to assess dimensions and functionality

Refined the design to ensure usability and efficiency

The veterinarian left CMEC with a fully developed design and manufacturing-ready CAD files. They have since secured a manufacturer and started production. Soon, this custom-designed surgical tool will be available to veterinarians across the country.

Custom Display Stand

Another unique project was a custom display stand. The entrepreneur behind it came to CMEC with some initial CAD designs but needed significant refinement. The concept evolved multiple times, requiring Angela to:

Make precise modifications to the CAD files

3D print test models to evaluate functionality

Implement four different design iterations

This project was particularly complex because it involved integrating LED lighting, remote wireless controls, and CNC-engraved acrylic plates. Additionally, a battery-powered system was later added for portability during one of the redesigns. Angela also used 3D printing pens for minor repairs and modifications.

After extensive testing, the first fully functional display stand was completed. Though the entrepreneur paused development, they have since reached out to continue the project with AJ Mechanical Design, seeing Angela’s expertise as invaluable.

You can learn more about the Custom Display Project on their website: Legacy Light Concept Page

Building the Future of Product Design

Angela’s time at CMEC provided her with the experience of turning rough ideas into refined prototypes and helping entrepreneurs take their designs to the next level. Whether a client has a fully developed concept, an early-stage prototype, or simply an idea sketched on paper, AJ Mechanical Design can guide them through the roadmap of product development.

Angela is passionate about helping innovators bring their ideas to life. Through her expertise in CAD modeling, prototyping, and product design, she continues to support entrepreneurs who are ready to create, innovate, and build something new.

If you’re looking for a skilled designer to bring your product idea to life, AJ Mechanical Design is ready to help!

References

Projects - Commercialization and Manufacturing Excellence Center - Purdue University Northwest. (2022, January 28). Commercialization and Manufacturing Excellence Center. https://www.pnw.edu/commercialization-manufacturing-excellence-center/projects/

Comments